+86 15968093247

+86 15968093247 Unlock Apparel's Potential with CLO3D

CLO3D is a 3D fashion design software. It creates virtual, true-to-life garment visualizations. This fundamentally changes traditional apparel development. Designers create real garments in real-time. They accurately see fabric, fit, and silhouette. This brings significant improvements in efficiency, cost savings, and design innovation. Major apparel companies like Adidas, Inditex, and Hugo Boss use CLO 3D. This highlights its critical role in modern fashion.

Key Takeaways

- CLO3D is a 3D fashion design software. It helps designers create virtual clothes. This makes the design process faster and more efficient.

- CLO3D saves money and helps the environment. It reduces the need for many physical samples. This means less waste and lower costs.

- CLO3D improves how designers work. It makes designs more accurate. It also helps teams work together better.

Traditional Apparel Design: Overcoming Key Challenges

Traditional apparel design faces many hurdles. These challenges often slow down the process and increase costs. They also limit how creative designers can be.

The Cost of Physical Sampling

Creating physical samples costs a lot of money. Each sample requires materials, labor, and shipping. For a beginner brand, the total cost from concept to a final approved sample can range from $200 to over $4,000. Simple garments might cost $200-$600, while complex designs can easily exceed $1,500.

| Cost Category | Range |

|---|---|

| Simple garments (total cost) | $200-$600 |

| Intermediate complexity garments (total cost) | $600-$1,500 |

| Complex/luxury garments (total cost) | $1,500-$4,000+ |

Sample revisions quickly add up. For example, if a team makes seven samples to get the fit right for one button-down shirt, the labor cost alone could reach $2800. This does not even include materials or shipping. Prototype costs, including materials and labor, typically range from $150 to $450 per item. Most styles need three or more iterations. This means a company developing 2,000 new products could spend over $17 million on development alone.

Material Waste in Development

Traditional design also creates a lot of waste. Factories waste 10–15% of all fabric during the development phase. This includes fabric used for prototypes and samples. This waste impacts the environment and increases production costs.

Bridging Communication Gaps

Designers often struggle to show their ideas clearly. Flat 2D sketches do not always capture how a garment will look or fit in real life. This can lead to misunderstandings between designers, pattern makers, and manufacturers. These communication gaps cause delays and require more revisions.

Limits on Design Experimentation

Trying new designs becomes hard with traditional methods. Each physical sample costs time and money. This makes designers less likely to take big risks or explore many different options. They often stick to safer choices to avoid extra costs and delays. This limits innovation and creative freedom.

How CLO3D Revolutionizes Apparel Development

CLO3D changes how apparel companies work. It offers solutions to many traditional design problems. This software brings efficiency, savings, and new possibilities to the fashion industry.

Accelerating Product Cycles with CLO3D

CLO3D dramatically speeds up the entire design process. Designers make changes and finalize designs much faster. This means products reach the market quickly. Companies keep up with the latest trends. The software also reduces the need for many physical prototypes. This saves money and shortens turnaround times.

Significant Cost Savings and Sustainability with CLO3D

Apparel companies save a lot of money using CLO3D. They rely less on physical samples and prototypes. This makes the sampling process smoother. It also cuts down on time and resources. Material consumption decreases significantly. The technology simplifies design development, saving both time and money.

Using CLO3D, companies reduce the time it takes to produce garments. They save on production costs and help protect the environment. 3D virtual simulation systems make decision-making faster. This reduces lead time. Cost savings and environmental benefits vary. Small companies might see increased labor costs offset savings. Large companies, like H&M, achieve both cost savings and environmental protection.

CLO3D helps companies reach their sustainability goals.

Since 2020, A&F Co. brands use virtual garments with CLO3D Fashion Design Software. Virtual garments let designers see fabric, fit, and silhouette digitally. This helps them communicate effectively without many physical samples. It reduces waste and time in production. Virtual garments also save resources used for manufacturing, shipping, and storing samples.

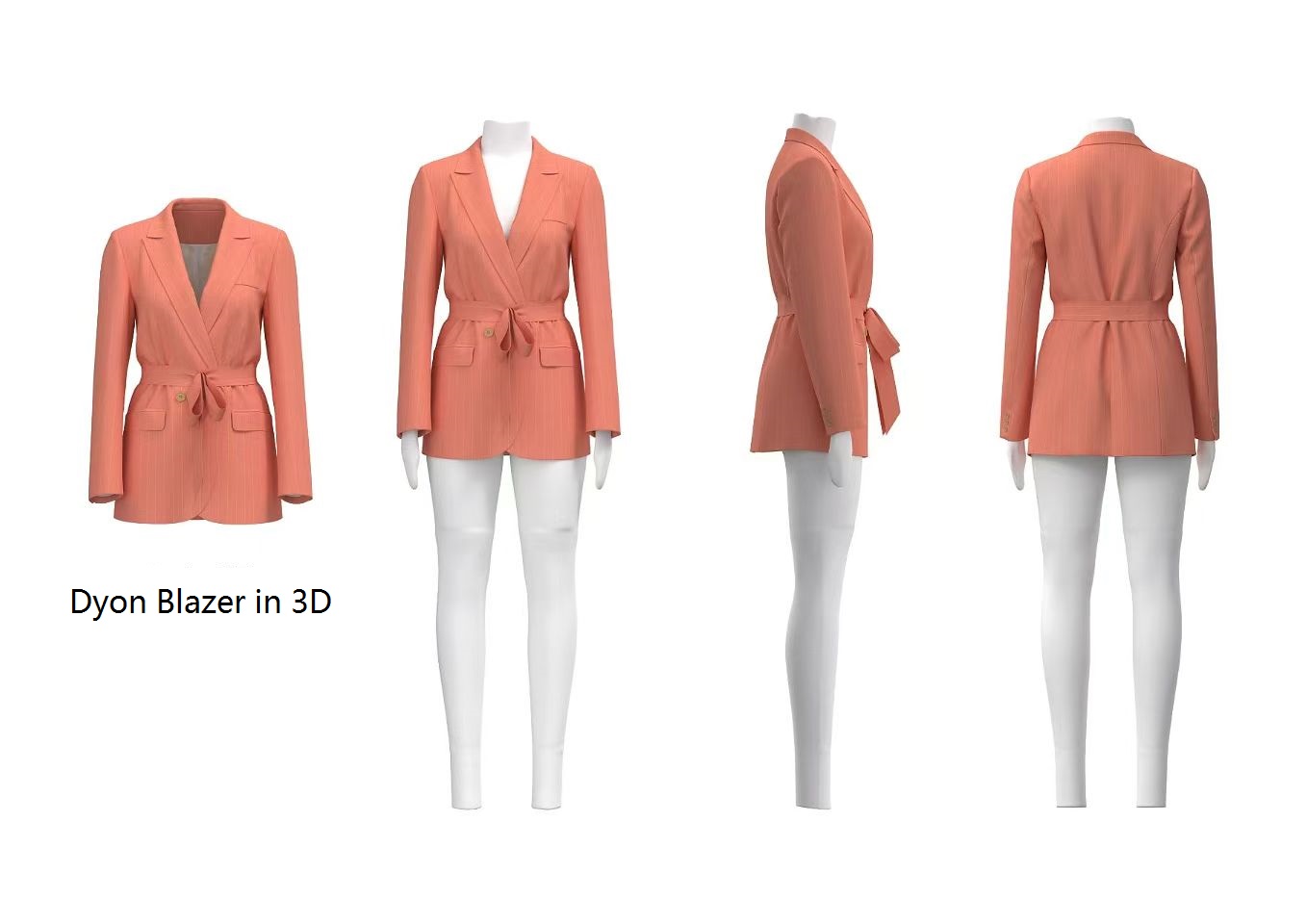

The software reduces the need for many physical sample iterations. It lets designers see 2D pattern edits on virtual samples right away. It also removes the need for photo shoots. Companies create photorealistic images of garments for sales, marketing, and e-commerce. Customers can see and buy items before physical production even starts.

Enhancing Design Accuracy and Collaboration via CLO3D

CLO3D improves how designers work together. It also makes designs more accurate. Everyone involved sees a clear, 3D representation of the garment. This reduces misunderstandings between designers, pattern makers, and manufacturers. Clear visuals mean fewer errors and less need for revisions. Teams can share and review designs virtually. This makes collaboration easier and more precise, no matter where team members are located.

Unleashing Creative Freedom with CLO3D

CLO3D gives designers more freedom to create. They can experiment with new ideas without the usual costs and delays. This means more innovation in fashion. A podcast episode mentions that 3D design, including CLO3D, boosts creative freedom. It also reduces waste and makes samples more accurate.

Designers can visualize and compare different fabric options. For example, they can see how cotton polyester French terry looks versus cotton polyester fleece for a sweater.

- This virtual testing helps designers understand how fabrics drape and feel. They do this without expensive physical samples or wasting time.

- This process of exploring fabrics virtually saves time. It also "sparks creativity." Designers freely try out different material choices.

Maria Posada says that an organized approach within CLO3D actually "enhances" creativity. This includes structuring CADs and workspaces. This systematic method makes the design process more efficient and consistent. It also makes it more transparent. This allows creativity to "flow freely." It does not get held back by disorganization.

Boosting Marketing and Sales with CLO3D Visuals

CLO3D visuals are powerful tools for marketing and sales. Companies create stunning, photorealistic images and animations of garments. They use these visuals for online stores, social media, and digital showrooms. This lets customers see products in detail before they even exist physically. It generates excitement and pre-orders. This approach also eliminates the need for expensive photo shoots. It saves time and money while creating high-quality marketing content.

Practical Applications of CLO3D Across the Value Chain

CLO3D offers powerful tools that impact every stage of apparel development. From initial design to final sales, it streamlines processes and enhances outcomes.

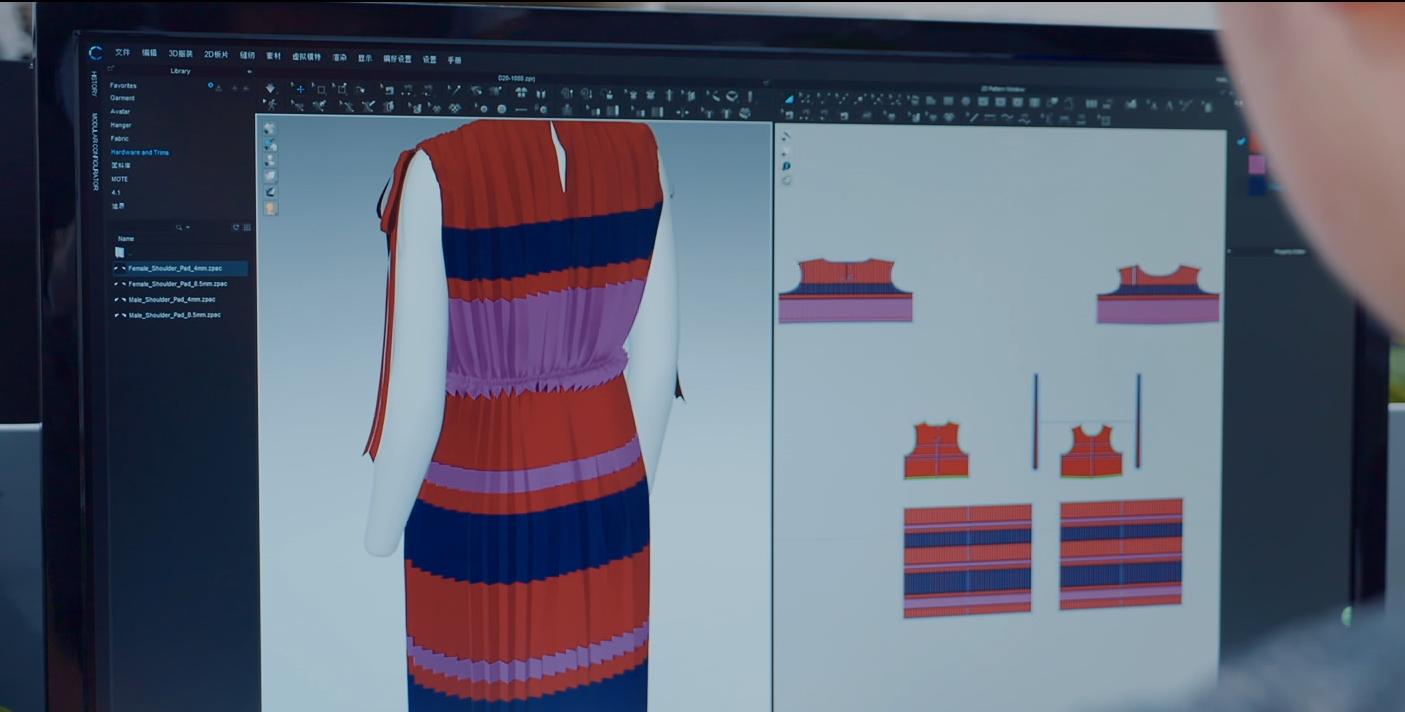

CLO3D for Design and Pattern Making

Designers use CLO3D to bring their ideas to life with precision. They can draft simple patterns, like a basic bodice or a straight skirt. Then, they modify these basic patterns into complex designs. This includes adding fullness, creating style lines, and adjusting the fit. Designers even create intricate details, such as a collar from scratch. This involves taking measurements, establishing a neckline base, drafting the shape, and making adjustments. They then simulate it on a garment.

The software also helps with many other pattern-making tasks. It creates virtual 3D samples and generates printable patterns. Designers develop slopers and manipulate darts. They also create pleats, gathering, and smocking effects. CLO3D imports pattern files from other programs and traces patterns from images. It exports files for printing and creates colorways. Users edit textures, prints, graphics, and embroidery. They also create custom trims and hardware.

Optimizing Fit and Sizing with CLO3D

CLO3D helps designers achieve the perfect fit for many body types. It allows for extensive avatar customization. Users adjust breast shape, joint positions, and other body parameters. This helps them design for a variety of figures. They also adjust model sizes to test garments on diverse body shapes. This reduces the need for physical prototypes. Real-time simulation instantly shows fabric behavior. Users test different materials and how they drape on various body forms.

CLO3D makes precise pattern making easier. It requires calibration between physical and digital assets for accurate fit. Users create digital copies of existing blocks and manikins. They also set physical manikins to baseline CLO3D avatars. This helps check tailoring forms. The software lets users adjust collision offsets between the avatar and garment. This helps them understand fit tolerance. Fabric physical presets and fit scales adjust to a baseline block. This allows for accumulated production control for various grading sizes. For diverse body types, using multiple baseline blocks is a good idea. For example, a size 10 and an extra-large for females helps with grading. This is especially true for garments where body silhouettes change a lot, like sportswear. This approach minimizes risk and improves digital fit quality for specific markets. It moves beyond a "one avatar character adjustment fits all" approach.

Realistic Material Simulation in CLO3D

CLO3D excels at showing how different materials will look and behave. Users set any fabric characteristics to achieve realism. Customizable properties include extensibility, drape, weight, stiffness, thickness, gloss, and roughness. The software offers high accuracy in fabric draping and material properties. It has a rich material library with customizable properties. These include weight, elasticity, and thickness. This makes it ideal for replicating various fabric types. CLO 3D provides highly accurate fabric simulations. It captures the drape, texture, and behavior of many materials. This lets users visualize how a garment will appear and move before physical production.

Virtual Prototyping and Sampling with CLO3D

Virtual prototyping with CLO3D transforms the sampling process. Designers create digital versions of garments. They test designs, make changes, and refine fit without cutting a single piece of fabric. This significantly reduces the number of physical samples needed. It saves time, money, and resources. Teams review and approve designs virtually. This speeds up decision-making and shortens the product development cycle.

CLO3D for E-commerce and Digital Showrooms

CLO3D provides powerful tools for marketing and sales. It exports tech packs, DXF patterns, and rendered visuals. These are all useful for actual production. It supports creative storytelling and practical execution. This applies to presentations for factories, clients, or creating e-commerce content.

CLO allows designers to create lifelike virtual garments. These are "digital twins" of physical garments. Designers test fit and functionality. They visualize garments in various virtual environments. The software is famous for its realistic simulations of fabrics, draping, and garment movement. This helps fashion designers and brands reduce the time and cost of traditional sample-making. Creating 3D garments allows for many iterations. This further reduces the time and cost linked to physical sample production. It leads to a time-saving, eco-friendly, and sustainable workflow.

CLO provides features like virtual showrooms, web techpacks, and visual boards. These cover the entire process from sample production to actual clothing production through 3D design. This creates a more efficient digital workspace for collaboration. CLO-SET showcases collections in an immersive 360° environment. It has a powerful 3D asset viewer. This offers buyers an interactive experience to explore design details in a virtual space. Users create stunning 360° backdrops in CLO-SET. These range from custom 3D layouts to on-site store environments. They add 3D designs, renders, and other artworks to build unique experiences. Showrooms publish and share easily with partners via a simple link. This requires no additional registration. It enhances collaboration by providing seamless access to engaging virtual spaces. CLO supports generating new revenue streams and community engagement. This happens through virtual clothing sales in the metaverse, digital exhibitions, and virtual fittings. After designing digital garments, users create augmented reality (AR) filters for virtual try-ons at points of sale. Features like the AR Mirror optimize CLO garments for digital environments. These include gaming and the metaverse. Digital garments designed in CLO animate further. This allows for creating entire digital worlds. Seamless integration into software like Unreal Engine happens through plug-ins and partnerships. This enhances real-time rendering, physics-based fabric simulation, and immersive visualization for virtual showrooms and interactive retail.

Implementing CLO3D: Strategic Considerations

Bringing CLO3D into your business requires careful planning. Companies need to think about investment, training, and how it fits with current operations. A smooth transition helps unlock its full potential.

Understanding CLO3D Investment and ROI

Adopting CLO3D means an initial investment. This includes software licenses and potentially new hardware. However, the return on investment (ROI) can be substantial. Companies save money by reducing physical samples and speeding up product development. These savings often outweigh the initial costs quickly. They also gain a competitive edge with faster time-to-market and more innovative designs.

Essential Training for CLO3D Proficiency

To get the most from CLO3D, teams need proper training. Designers should master several key areas:

- Mastering CLO: This includes modeling, finishes, texturing, and rendering.

- Learning Blender: This enhances realism, helps craft environments, props, and compelling narratives.

- Pattern Making: This covers dart manipulation, style lines, added fullness, and grading.

- Fabric Development: Focus on understanding fabric types, weave distinctions, and material properties for realistic texture.

- Animation and Avatar: This involves avatar structure, customization for rigging, and progressing to intricate animations.

Before starting, designers should have basic pattern-making knowledge and comfort with digital tools. Training aims to help them master 3D tools for precise pattern creation, optimize workflows for high-quality renderings, and use AI to accelerate design.

Integrating CLO3D into Existing Workflows

CLO3D works as a complete digital garment sampling system. It offers a full workflow within one software. It provides strong documentation for patterns and tech packs. This documentation goes into its cloud-based CLO-SET system for digital asset management. For best results, companies should:

- Ensure Seamless Integration: CLO3D should work well with existing software like PLM systems or Adobe Illustrator. This avoids data silos and keeps workflows smooth.

- Provide Comprehensive Training: Offer formal training, online tutorials, or hands-on practice. This helps the team use CLO3D effectively, increasing comfort and adoption.

- Streamline Processes: Choose tools that boost productivity and fit easily into the workflow. This helps achieve efficiency goals without adding complications.

CLO3D stands as a vital tool for modern apparel businesses. It helps them achieve efficiency, sustainability, and innovation. Companies that adopt CLO3D stay competitive. They unlock their full potential in the evolving fashion landscape. Embrace CLO3D today. It will transform your design process, reduce waste, and accelerate time-to-market.

FAQ

What is CLO3D?

CLO3D is 3D fashion design software. It creates virtual, true-to-life garments. Designers visualize fabric, fit, and silhouette instantly. This changes how apparel develops.

How does CLO3D save money for businesses?

CLO3D significantly reduces physical samples. This cuts costs for materials, labor, and shipping. It also speeds up design, saving valuable time and resources.

Does CLO3D help the environment?

Yes, CLO3D reduces material waste from sampling. It also lowers resource use for manufacturing and shipping. This helps companies meet sustainability goals.